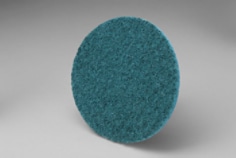

3M™ Scotch-Brite™ Paño 7447 PRO, 6"x 9", A Grano Muy Fino

Identificación 3M

61500299922

3M™ Cubriton™ II Rollo de Tela 984F, 52in x 50yds 80+ YF-peso, 1/Caja

Identificación 3M

60440232043

3M™ Scotch-Brite™ Paño Abrasivo 7445, 6"x9" F Grano Super Fino

Identificación 3M

61500123213

3M™ Trizact™ Finesse-it™ Rollo de Discos Abrasivos con Lámina 466LA, 1-1/4 pulgadas sin agujeros A5, 500 discos por rollo...

Identificación 3M

60020006395

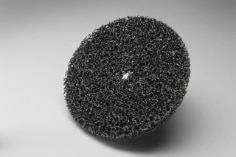

3M™ Scotch-Brite™ Cepillo Radial Bristle 6"X1/2"X1" Grano 50

Identificación 3M

61500151461

UPC

00048011276052

3M™ Scotch-Brite™ Cepillo Radial Bristle 6"X1/2"X1" Grano 36

Identificación 3M

61500151446

UPC

00048011276038

Disco Flap 3M™ 577F, T29, Grano 40, 114 mm x 22 mm, 10/Caja

Identificación 3M

60440263469

Disco Flap 3M™ 577F, T29, Grano 60, 114 mm x 22 mm, 10/Caja

Identificación 3M

60440263477

3M™ Scotch-Brite™ Disco para Limpieza y Raspado, 6inch x 1/2inch

Identificación 3M

61500120722

Banda Acondicionadora de Súperficies Scotch-Brite®, 1/2 pulgadas x 18 pulgadas, A VFN, 20 por caja

Identificación 3M

61500072683

3M™ Cubriton™ II Rollo de Telas 947A, 52in x 50yds 120+ X-peso, 1/Caja

Identificación 3M

60440311250

Almohadilla de Mano de Uso General Scotch-Brite™ 7447, Muy Fino, 6 in x 9 in, 20 por caja, 3 cajas por paquete

Identificación 3M

61500123239

3M™ Trizact™ Rollo de Tela 237AA, 66cm x 4572cm A100 X-peso, 1/Caja

Identificación 3M

60410010965

3M™ Trizact™ Rollo de Tela 237AA, 66cm x 4572cm A45 X-peso, 1/Caja

Identificación 3M

60410010932

3M™ Trizact™ Rollo de Tela 237AA, 26 in x 50 yd A16 X-peso, 1/Caja

Identificación 3M

60410010916

Disco Acondicionador de Superficies SC Scotch-Brite™

Identificación 3M

61500121183

Disco Acondicionador de Superficies Scotch-Brite™, 7'' x NH, A VFN, 25 por caja

Identificación 3M

61500121167

Disco Acondicionador de Superficies SC Scotch-Brite™

Identificación 3M

61500014222

3M™ General Purpose Disco de Corte, 14'' x 3 mm x 1'' G30, 5 Discos/Caja

Identificación 3M

60440281826

Rollo de Tela 3M™ Cubitron™ II 984FX Pro, Grano 36+, Peso YF, 1320.8 mm x 91.44 m, 1/Paquete

Identificación 3M

60440406969

Rollo de Tela 3M™ Cubitron™ II 984FX Pro, Grano 36+, Peso YF, Configurable

Identificación 3M

60000366496

3M™ Scotch-Brite™ Esponja abrasiva Fina 115mm x 140mm

Identificación 3M

EC000101971

3M™ Scotch-Brite™ Esponja abrasiva Super Fina 115mm x 140mm

Identificación 3M

EC000101997

3M™ Wetordry™ Finesse-it™ Rollo de Discos Abrasivos con Soporte de Papel 401Q, 1-3/8 pulgadas (35 mm) sin agujeros, 1500 ...

Identificación 3M

60010017592

Hoja Abrasiva con Respaldo de Papel 3M™ 230U, Grano 60, 225 x 275 mm, 50 Hojas/Caja

Identificación 3M

HB004071278

3M™ Scotch-Brite™ Roloc™ Disco Acondicionador de Superficies 4" sin agujeros A Muy Fino

Identificación 3M

61500049376

3M™ Scotch-Brite™ Roloc™ Disco Acondicionador de Superficies 4" sin agujeros A Mediano

Identificación 3M

61500049384

3M™ Scotch-Brite™ Roloc™ Disco Acondicionador de Superficies 4" sin agujeros A Grueso

Identificación 3M

61500049392

3M™ Scotch-Brite™ Roloc™ Disco Clean & Strip XT Púrpura 4 1/2"

Identificación 3M

61500151263

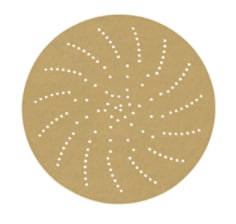

Disco de papel 3M Xtract™ 236U, 55514, 6 in P400 C-weight, 50 por caja 250 por paquete

Identificación 3M

XA012057833